CALB

EU Stock-4PCS 3.2V CATL 314Ah Grade A Lifepo4 Battery Cells Rechargeable for EV Solar Energy Free Shipping & Free Tax & With Cells

EU Stock-4PCS 3.2V CATL 314Ah Grade A Lifepo4 Battery Cells Rechargeable for EV Solar Energy Free Shipping & Free Tax & With Cells

Couldn't load pickup availability

Specifications(CATL 314Ah)

| Rechargeable | |

| Nominal Voltage | 3.2V |

| Nominal Capacity | 314Ah |

| Internal resistance | ≤0.3mΩ |

| Charging cut-off voltage | 3.65V |

| Discharge cut-off voltage | 2.5V (>0℃); 2.0V (≤0℃) |

| Height | 207±0.4mm |

| Length | 174.4±0.3mm |

| Thickness | 71.4±0.3mm |

| Center distance of pole | 123±0.3mm |

| Battery Weight | 5.42±0.16kg |

| Standard charge | 0.5C |

| Standard discharge | 0.5C |

| Max charge current | 1C |

| Max discharge current | 1C |

| Charging Temperature | 0~60 ℃ |

| Discharge temperature | -20~60 ℃ |

| Cycle life | 8000 Cycles |

What's in the Box

Fast DDP shipping from Poland 5-7 working days:

Materials

Materials

lithium-iron phosphate,aluminum

Shipping & Returns

Shipping & Returns

We will ship the battery from the EU warehouse,usually, it takes 10 days for the delivery.

Dimensions

Dimensions

(L*W*H):445*160*128mm(100Ah module)

(L*W*H):620*174*210mm(280Ah module)

Share

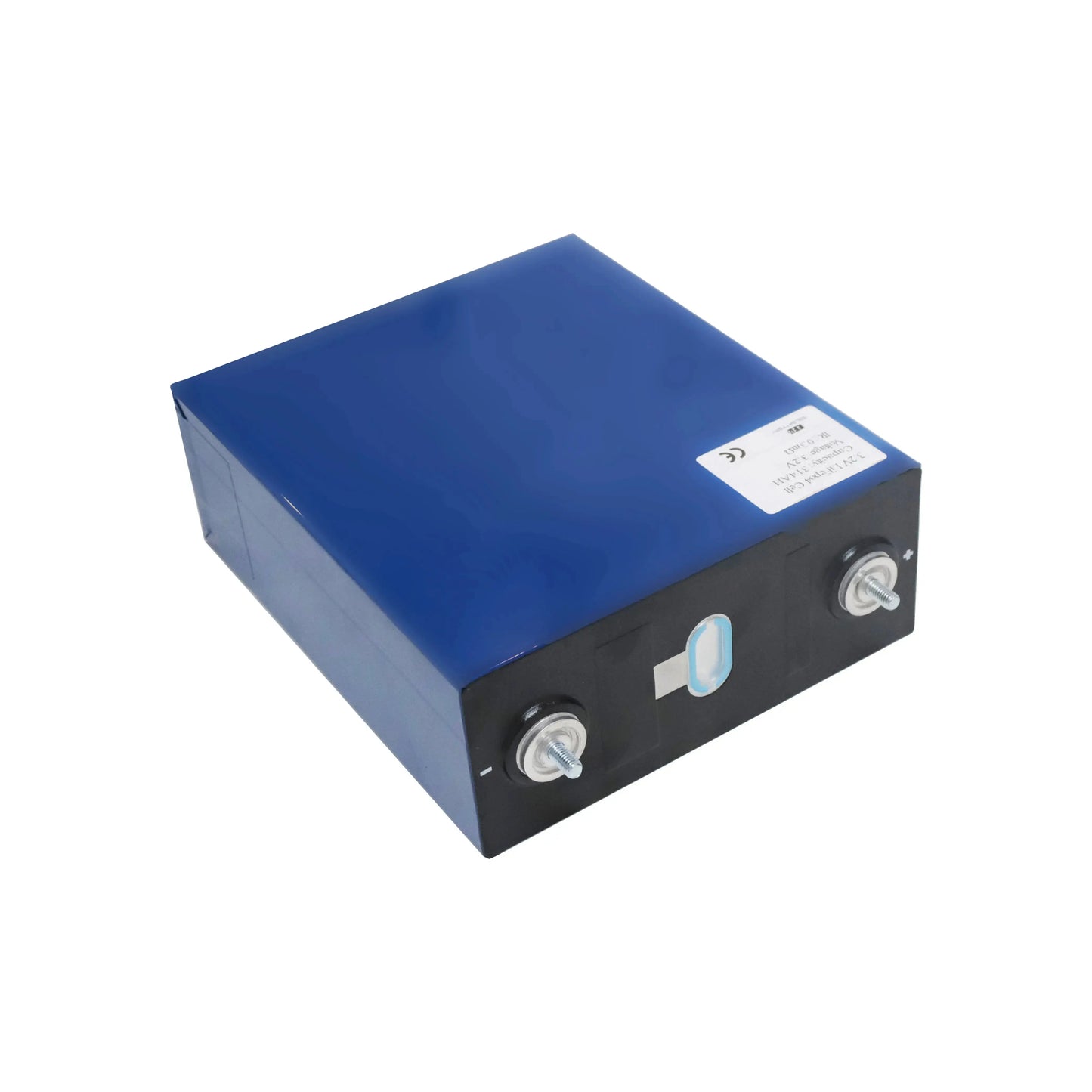

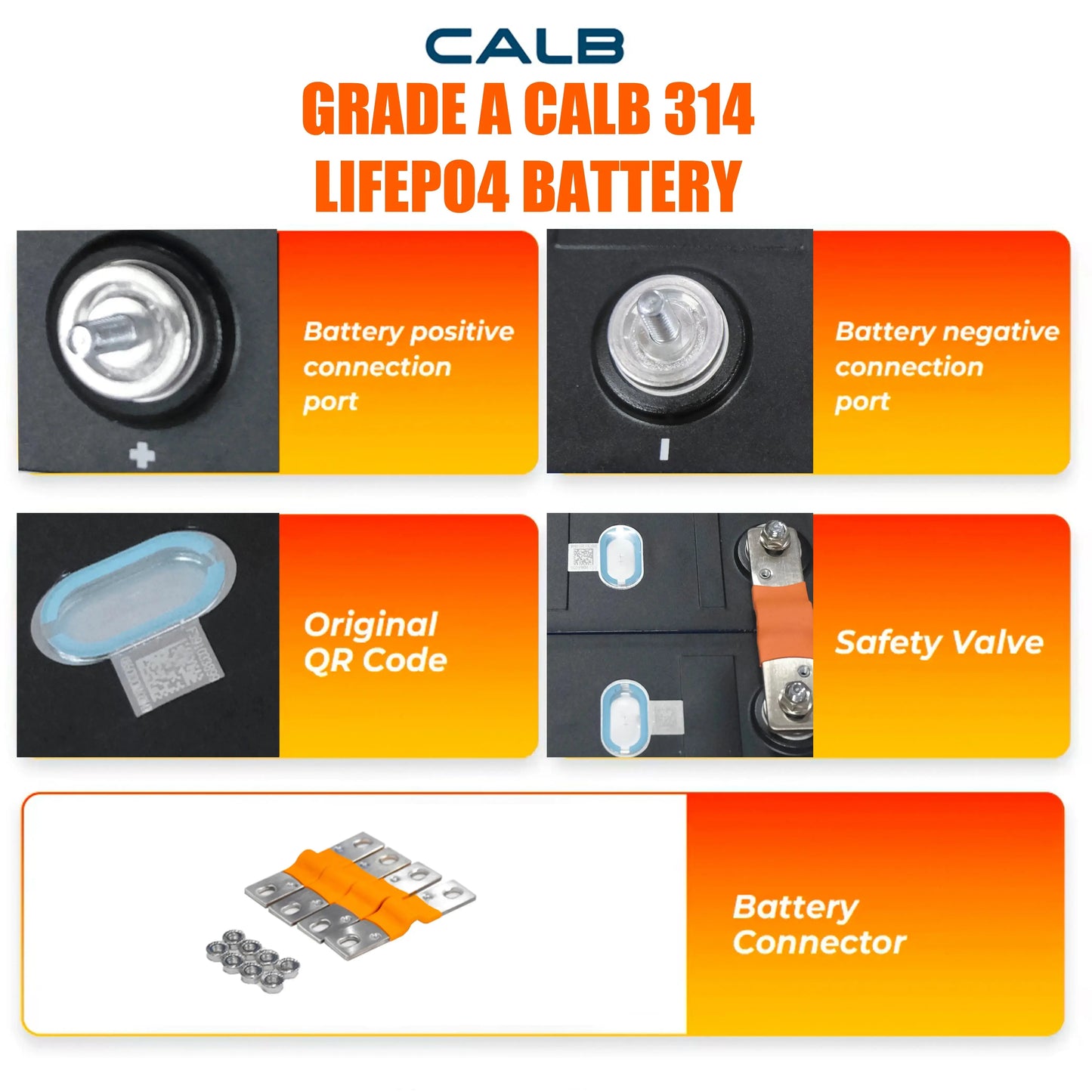

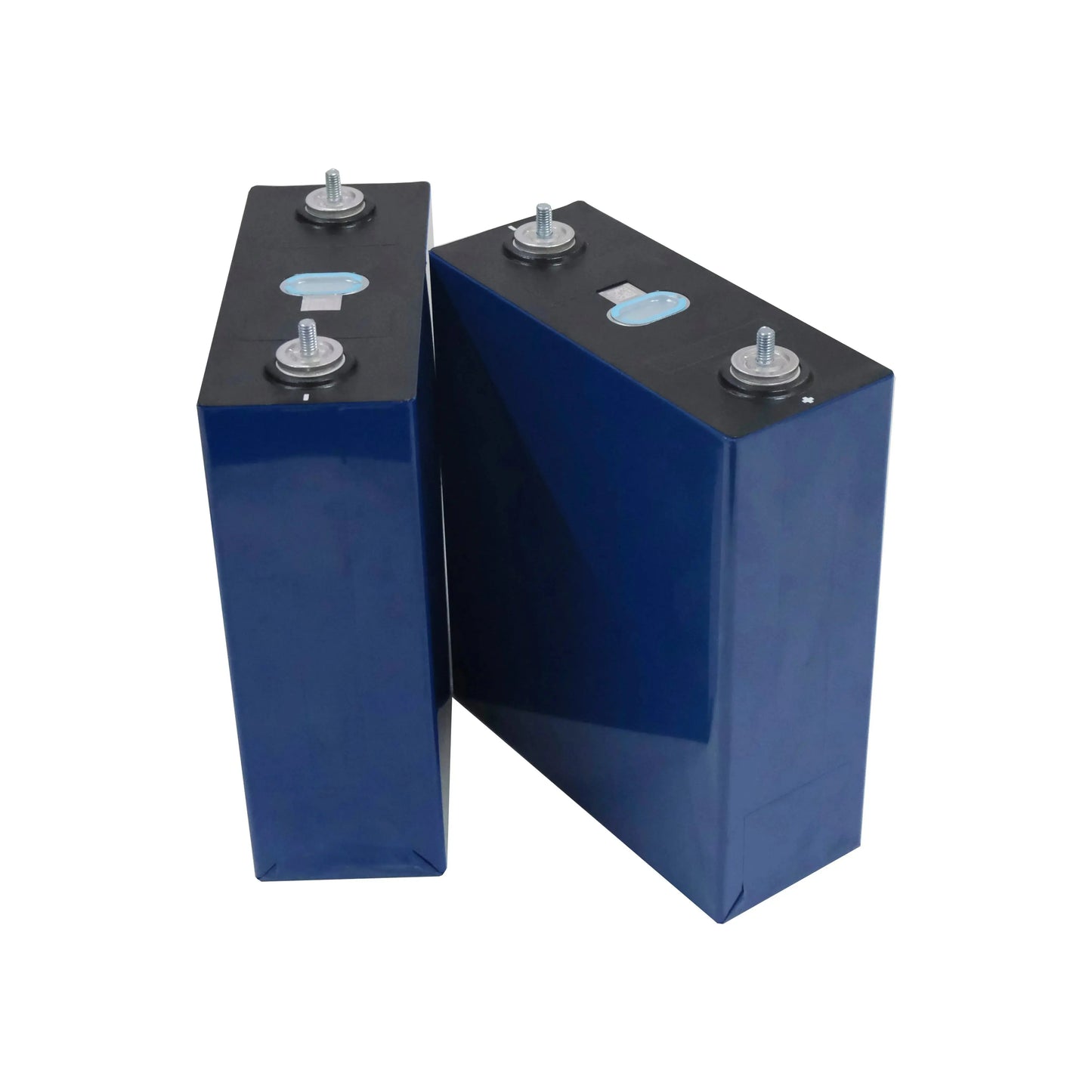

CALB 314 M6 studs Grade A LiFePO4 Cells

Upgrade your energy storage system with CALB 314Ah Grade A LiFePO4 Battery Cells featuring M6 studs, designed for superior performance, safety, and long cycle life. These high-capacity lithium iron phosphate cells deliver stable 3.2V output, making them ideal for solar energy storage, RVs, electric vehicles, off-grid systems, and DIY battery packs.

With precision-engineered M6 terminal studs, installation is secure and reliable, ensuring excellent conductivity and durability. CALB’s advanced manufacturing guarantees over 6,000 cycles, high energy density, and unmatched consistency across cells.

Perfect for renewable energy projects, backup power, and EV conversions, the CALB 314Ah LiFePO4 cells offer exceptional efficiency, deep cycle capability, and long-lasting reliability.

Worldwide Business

If you want some customize and have some special requirements, welcome to contact us for the quotation(another battery cells are available).